STEP 1

KNOW THE PAPER TYPE

Choosing the correct paper rolls to order is not always easy. To make things more complicated, there are three different types of paper material, Bond, Thermal and carbonised paper rolls

Thermal Rolls use heat to produce text or imaging. Thermal paper Rolls are very sensitive to heat and friction. Thermal Rolls may have a glossy or smooth top coat.

Bond Rolls require ribbon/ink to produce text and imaging. Bond paper has similar resemblance to standard copy paper and has rough surface.

Carbonised Rolls are a 2 or 3 ply roll, when pressure is applied on the top layer it copies to the beneath layer, giving you two copies.

Telling Bond and Thermal apart – To tell if you have Bond or Thermal paper, Scratch the top side of the roll HARD with your fingernail, if a black or dark mark is left – Then it is Thermal as it is reacting to the friction. If nothing appears but a light mark, it is Bond Paper.

STEP 2

MEASURING THE PAPER SIZE

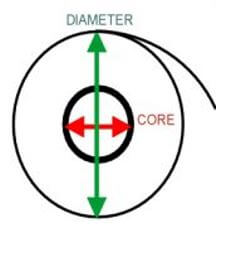

There are 3 different measurements needed when determining the size of a paper roll you will need for you machine. They are Width, Diameter and Core Size.

When measuring rolls, The Width is the most important measurement. When measuring the width, you must measure from edge to edge straight across. This is to ensure that you are purchasing the correct size for the print to fit nicely.

The Diameter is measured from side to side, directly through the core hole. The best way to get an accurate measurement is to put the roll on a flat surface get a ruler and measure, this way the roll is stable and you can use both hands to measure accurately.

The Core Size, in many cash registers you will notice that they don’t have a spindle for the roll to sit on to, so if this is the case with your machine the core size won’t matter to much. But for example, when you have a spindle the core size has to be matched correctly otherwise the roll won’t fit on or the roll will be too loose and won’t move functionally.

The Width

The Diameter

The Core

Go to STEP 3

For Labels

Labels have many measurements that must be known ensure the correct label is ordered.

STEP 1

KNOW THE LABEL TYPE

Choosing the correct labels to order is not always easy. To make things more complicated, there are two different types of paper material with a very similar names, Direct Thermal and Thermal Transfer. You can also sometimes use Direct thermal labels in a Thermal Transfer printer but not vice-versa.

Direct Thermal labels use heat to produce text or imaging. Thermal labels are very sensitive to heat and friction. Thermal label have a glossy like top coat.

Thermal Transfer Labels require ribbon to produce text and imaging. Thermal Transfer Labels are typically used for specialty applications.

Now, we need to know the labels are blank or pre-printed labels.

Telling Direct Thermal and Thermal Transfer apart:- To tell if you have Direct or Transfer labels, scratch the top side of the label HARD with your fingernail, if a black or dark mark is left, then it is Thermal. The label surface as it is reacting to the friction. If nothing appears but a light mark, it is a Thermal Transfer Label.

STEP 2

MEASURING THE LABEL SIZE

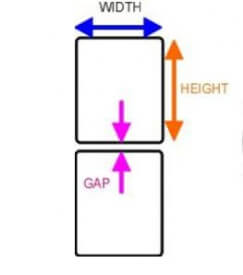

There are 5 different measurements needed in addition to the pre-printed sections when determining the size and type of a paper roll you will need for you machine. They are Label Height, Label Width, Label Gap, Roll Diameter and Core Size.

When measuring labels, The Width and The Height is the most important measurement. When measuring the width, you must measure from label edge to label edge straight across. DO NOT measure the backing paper. This is to ensure that you are purchasing the correct size for the print to fit nicely.

The Core Size, This can be a critical measurement for some machines. The Core is to be measured from inner diametre to inner diameter, be sure to measure this accuralty otherwise your roll wont fit the machine, for example, the core size has to be matched correctly otherwise the roll won’t fit on the spindle or the roll will be too loose and won’t move functionally.

The Diameter is measured from side to side, directly through the core hole. The best way to get an accurate measurement is to put the roll on a flat surface get a ruler and measure, this way the roll is stable and you can use both hands to measure accurately.

The Label Gap is not as critical as the previous measurements as most printers or scales can adjust for this. It is typically 2-3mm.

Now we can proceed to what (if anything) is pre-printed on the label by the factory.

Width x Height x Core Size x Diameter

Width, Height and Gap

Diameter and Core

STEP 3

ORDERING ROLLS

This is the easiest step of the three, ordering the correct rolls. Now that you know how to measure the correct size roll you can place an order for your rolls!

If you are having trouble working out the correct size, You can speak to one of our friendly staff members about your options, Contact our office on 07 5443 2744, email us at info@ebesuncoast.com.au

Leave A Comment

You must be logged in to post a comment.